The MOMO/WELD Group – manufacturers of ADV.1, MOMO, WELD, CCW, and Forgestar premium wheels – have received the prestigious TÜV Verification Certification for their production facilities. The certificate was issued by TÜV Austria.

The TÜV quality certification is respected worldwide. It is awarded only to select companies that clearly demonstrate the ability to meet the highest standards for engineering, manufacturing, quality, and safety. This achievement is an important milestone in the company’s goal to build and certify the world’s finest quality automotive, light truck and motorsport wheels. Furthermore, this certification is also a confirmation of the constant betterment and high goals instilled in our production, engineering and quality control processes, yielding utmost quality products for our customers.

Consistent with this certification, ADV.1 Wheels have announced a new, TÜV Certified product line bearing the German Kraftfahrtbundesamt seal of approval under provision 19.1 of the TÜV regulations. This approval allows the ADV.1 program to be certified and sold by dealers throughout Germany and Austria. Furthermore, it is the company’s plan to certify many of its brands worldwide under the exacting provisions of this certificate.

■ TESTING PROCEDURES

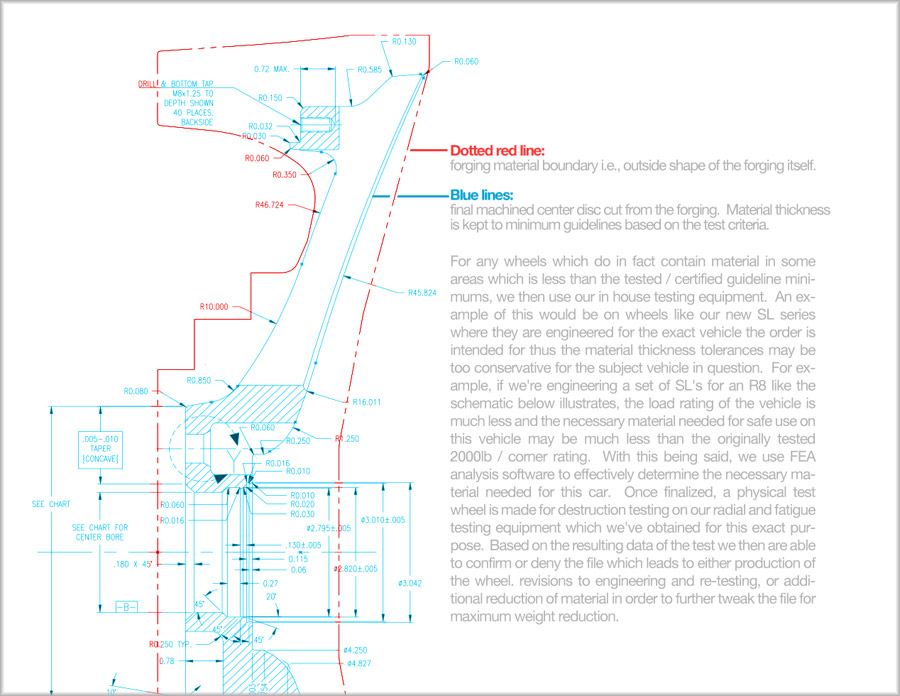

All of our forgings are initially engineered around a certain range of vehicle fitments / load ratings. Normally we design the forging die itself around a 2000lb. per corner load rating umbrella.

This means that so long as all wheels using this forging are engineered around the tested / certified material thickness minimums based on the test certification, no further testing is required unless an order violates these guidelines for any reason. To give you an example of this, see diagram below.

For any wheels which do in fact contain material in some areas which is less than the tested / certified guideline minimums, we then use ours in-house radial fatigue testing equipment.

An example of this would be on wheels like our the SL series where they are engineered for the exact vehicle the order is intended for thus the material thickness tolerances may be too conservative for the subject vehicle in question.

For example, if we’re engineering a set of SL’s for an R8 like the schematic below illustrates, the load rating of the vehicle is much less and the necessary material needed for safe use on this vehicle may be much less than the originally tested 2000lb / corner rating. With this being said, we use FEA analysis software to effectively determine the necessary material needed for this car. Once finalized, a physical test wheel is made for destruction testing on our radial and fatigue testing equipment which we’ve obtained for this exact purpose. Based on the resulting data of the test we then are able to confirm or deny the file which leads to either production of the wheel. revisions to engineering and re-testing, or additional reduction of material in order to further tweak the file for maximum weight reduction.

■ IN HOUSE RADIAL CORNERING / FATIGUE TESTING

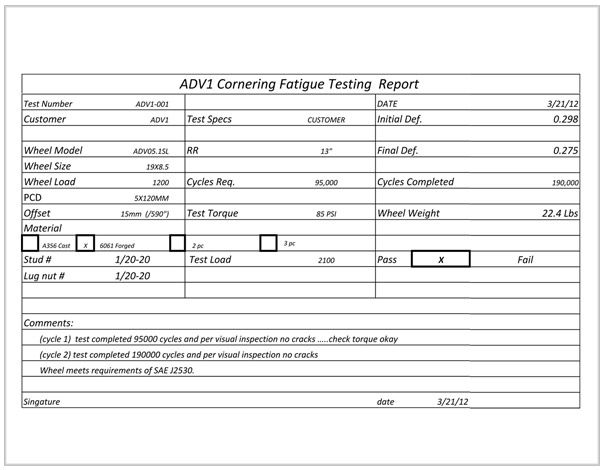

Our in house radial cornering / fatigue testing equipment also provides documentation on each subject tested. An example of such is shown below:

■ ADV.1 MATERIALS / SUPPLIERS

3 PIECE CENTER DISC FORGINGS:

Material: 6061 T6 Heat Treated Forged Aluminum Suppliers:

ASA / Centerline

1 PIECE MONOBLOCK FORGINGS:

Material: 6061 T6 Heat Treated Forged Aluminum Suppliers:

ASA

3 PIECE RIM HALVES

Material: 5051 Spun Forged Aluminum 6061 T6 Heat Treated Forged Aluminum Suppliers:

ARS / Triangle

MACHINING:

Performed:

In house at WELD Racing Machining / Production Facility

ENGINEERING / MILL PROGRAMMING:

Performed:

In house / WELD Racing Staff