ADV5.0 FLOW SPEC

FLOW FORMED WHEELS

When deciding which wheel designs to use to launch the ADV.1 Flow Spec program, it was a no brainer to go with the timeless wheel that cemented ADV.1 as the leader in aftermarket automotive wheel design over a decade ago. The ADV5.0 is a widely split 5 spoke that lends itself perfectly to performance coupes and sport sedans. Flow Spec is a manufacturing process known by many names such as flow forging and flow forming. This process allows for a stronger and lighter weight wheel over a traditional cast wheel. We’ve taken it upon ourselves to determine the best fitments for your vehicle. Theses preselected wheel fitments are readily available in two finishes to choose from, Platinum and Satin Black with no wait times. However, if your vehicle isn’t listed or you’d like to select your own custom width, offset, we offer a complete bespoke program that also gives you access to ADV.1’s full range of over fifty finish options.

ADV005 FLOW SPEC

FLOW FORMED WHEELS

The ADV005 Flow Spec Wheel is a bowed out split five spoke design that can most frequently be seen on luxury sports cars. Its angular silhouette perfectly complements the modern and aggressive styling found on the world’s most aerodynamic performance vehicles. Available in our recommended 20” and 21” fitments, in two finishes to choose from, Platinum and Satin Black with no wait times. If you desire a wheel that is custom tailored to your vehicle in terms of fit and finish we’ve got you covered with our Bespoke Program. Choose your width, offset, and any of ADV.1’s fifty custom color options.

ADV08 FLOW SPEC

FLOW FORMED WHEELS

Finding a wheel design that worked for both luxury big body sedans as well as SUV’s like the Mercedes G-Class proved itself to be a challenge, until now. The ADV08 blurs the lines between it being a split 8 spoke and a traditional mesh wheel. It’s large surface area is by far the best of the Flow Spec line to show off our two standard finishes of Satin Black and Platinum. If you’re looking for something outside of the box, ADV.1 offers a Bespoke Program that allows you to customize the color, width and even the offset of your 22” ADV08 so you can finely tune the wheels to fit your vehicle and style.

ADV.1 Wheels Flowspec Standard & Custom Finishes

Take a look at some of our standard & custom bespoke finishes for ADV.1 Flowspec Flow Formed wheels

ADV.1 Wheels Flowspec Standard & Custom Finishes

Take a look at some of our standard & custom bespoke finishes for ADV.1 Flowspec Flow Formed wheels

ADV.1 Concave Profile

Our Flowspec Flow Formed wheels are offered in concave and deep concave profiles. Please contact our sales team for the correct fitment information.

ADV.1 Concave Profile

Our Flowspec Flow Formed wheels are offered in concave and deep concave profiles. Please contact our sales team for the correct fitment information.

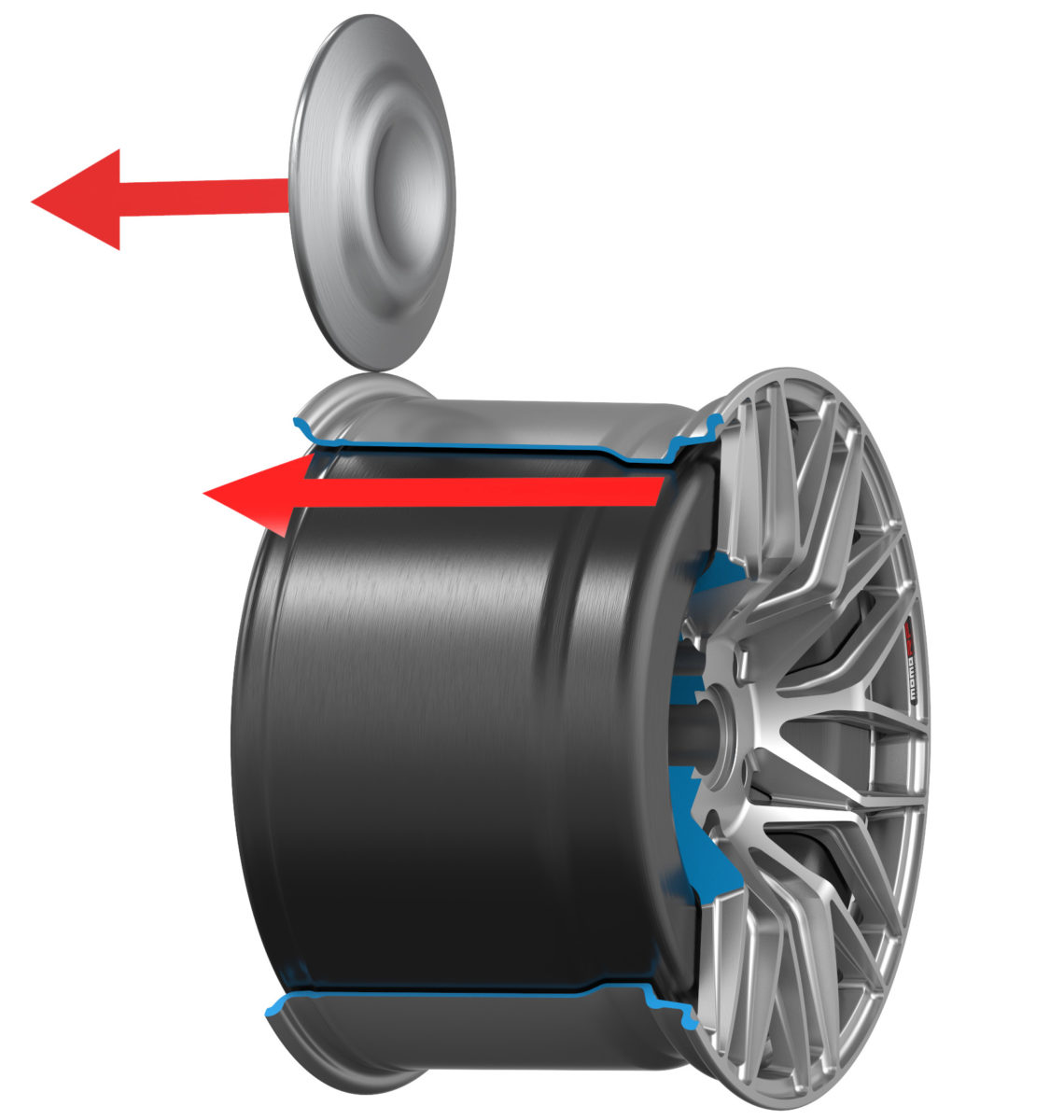

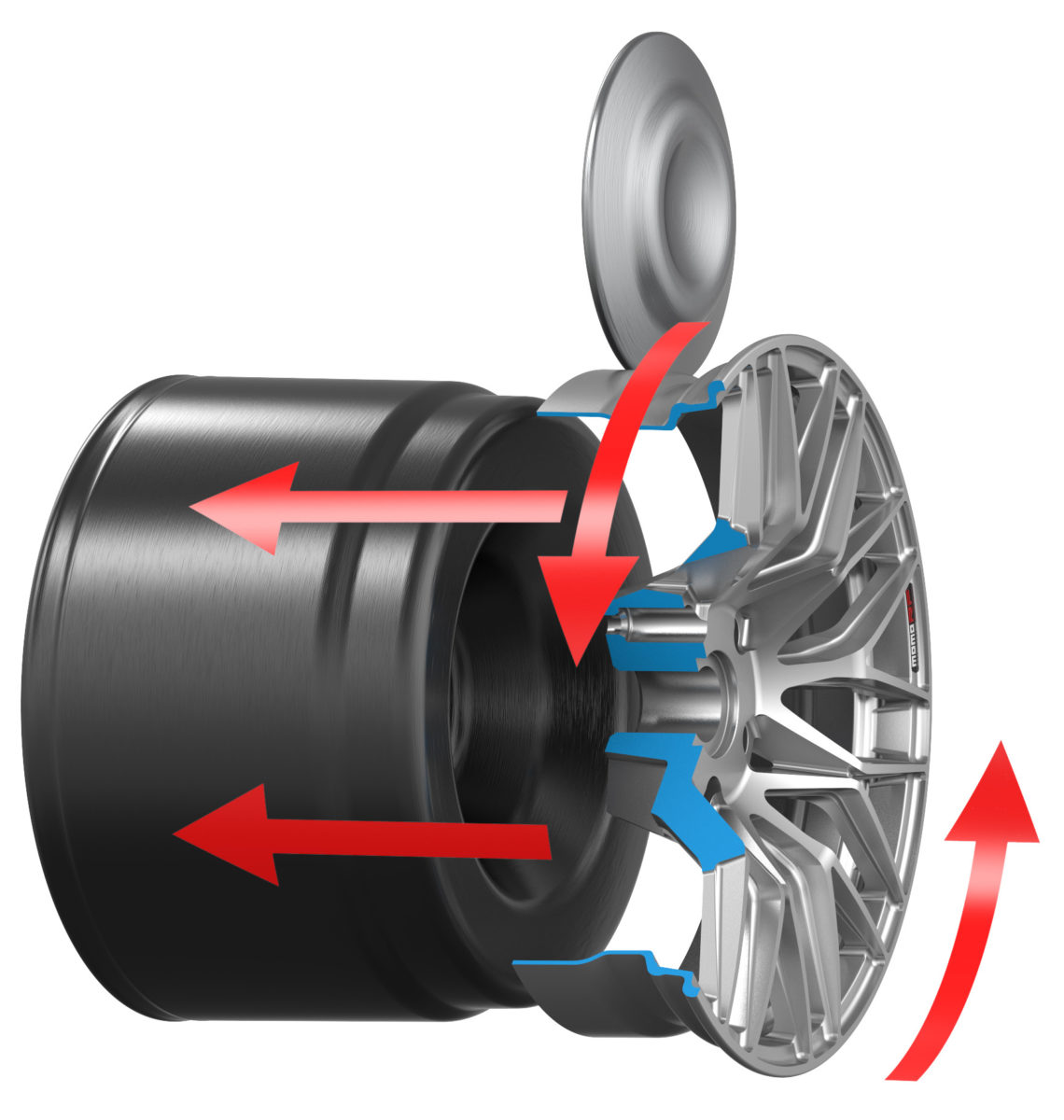

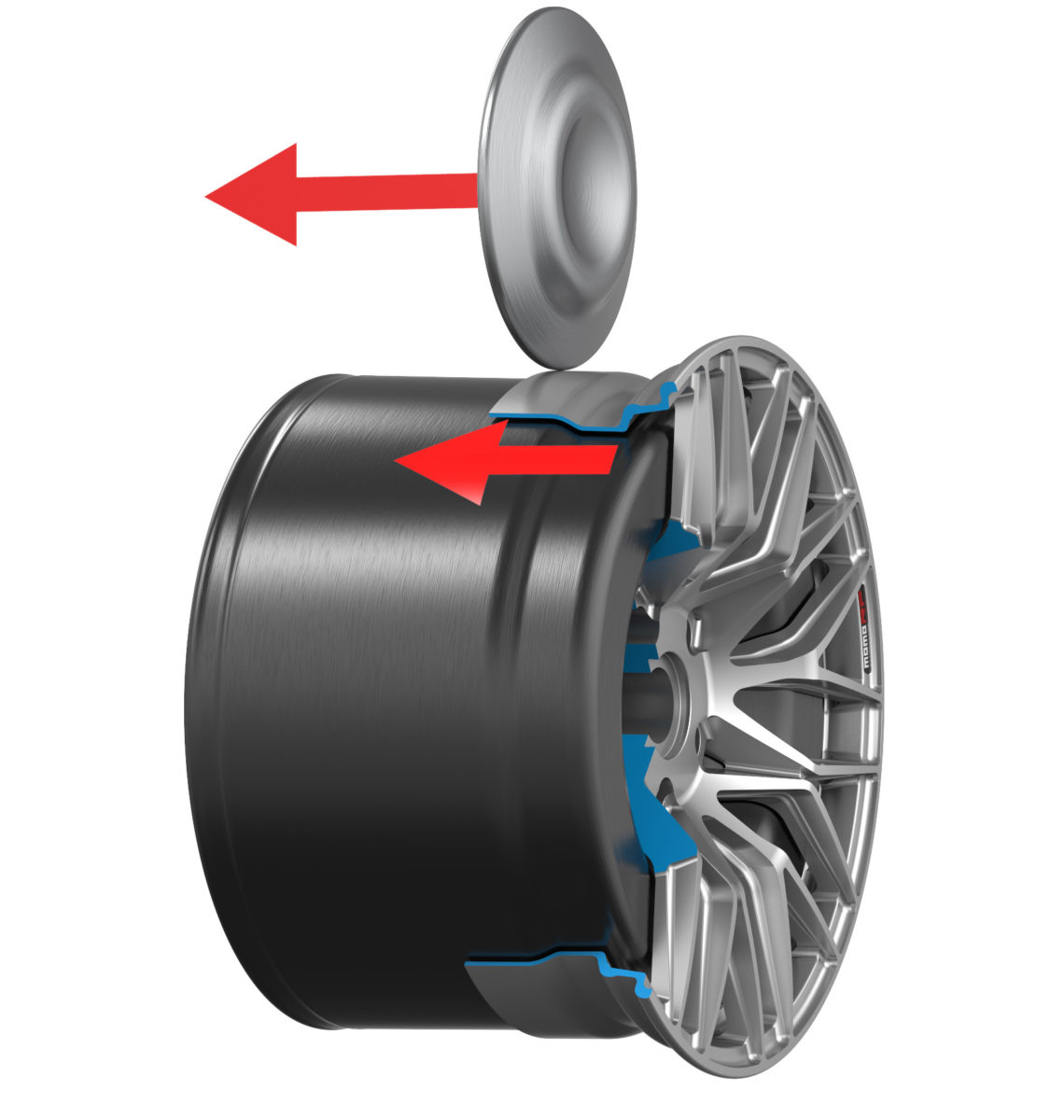

ADV.1 Flow forming Process

How flow formed wheels are made and what makes them a strong alternative to forged wheels at a more affordable price point.

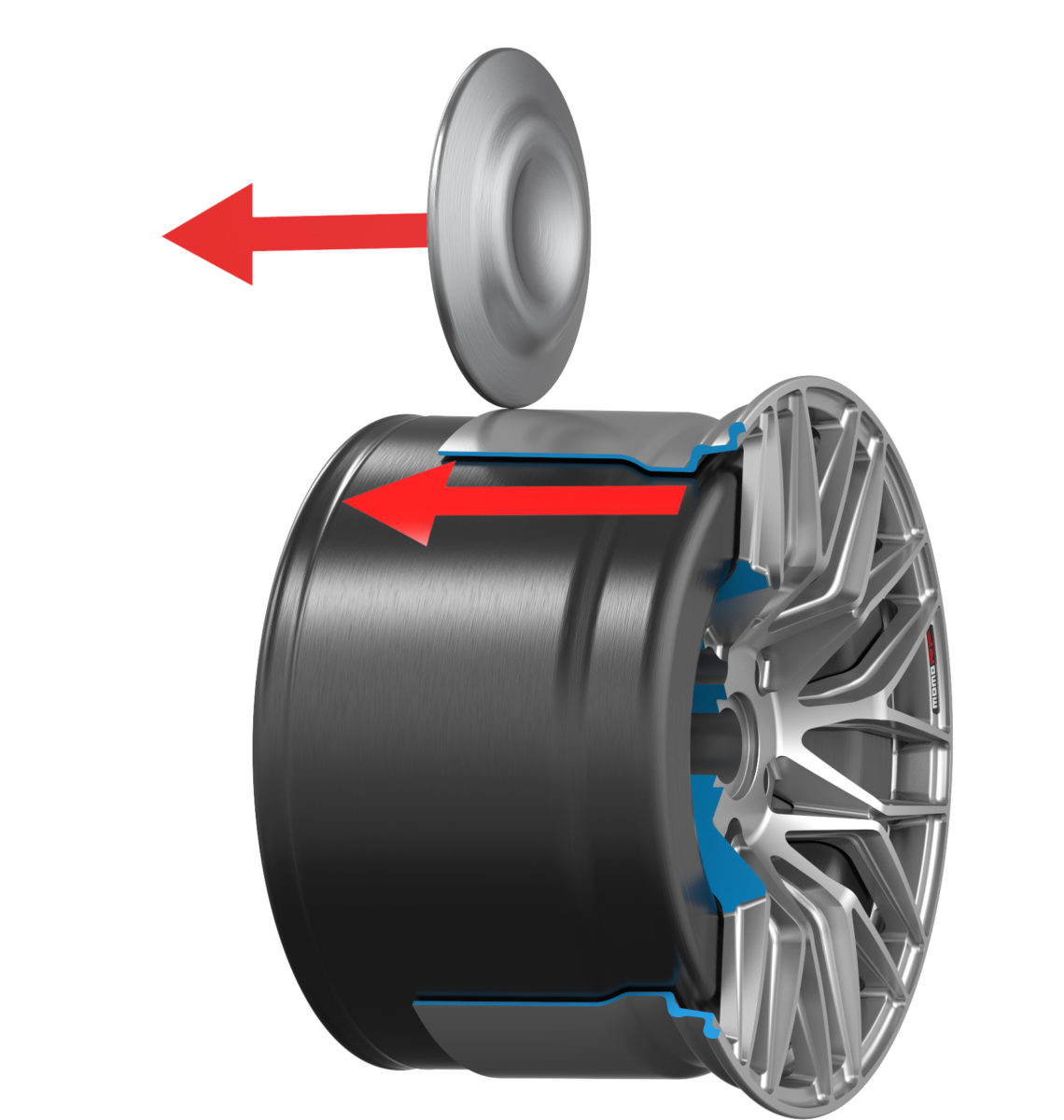

Flow Forming is an incremental metal-forming technique used to make wheels. With this technology, a disk is formed over a mandrel by one or more rollers using tremendous pressure and heat. The roller deforms the workpiece, forcing it against the mandrel. In turn, the metal is both axially lengthened and radially thinned at the same time. With this technique, the pressure exerted by the roller is highly localized and the material is incrementally formed. Flow forming subjects the metal material, where, thanks to heat & pressure applied to the wheel, the molecules of the aluminum are improved, creating a strong & lightweight wheel with characteristics similar to that of a forged wheel, but with a much lower price point. In turn, this makess flow formed wheels more affordable than their forged counterparts and stronger than cast wheels.

ADV.1 FlowForming Process

How flow formed wheels are made and what makes them a strong alternative to forged wheels at a more affordable price point.

Flow Forming is an incremental metal-forming technique used to make wheels. With this technology, a disk is formed over a mandrel by one or more rollers using tremendous pressure and heat. The roller deforms the workpiece, forcing it against the mandrel. In turn, the metal is both axially lengthened and radially thinned at the same time. With this technique, the pressure exerted by the roller is highly localized and the material is incrementally formed. Flow forming subjects the metal material, where, thanks to heat & pressure applied to the wheel, the molecules of the aluminum are improved, creating a strong & lightweight wheel with characteristics similar to that of a forged wheel, but with a much lower price point. In turn, this makess flow formed wheels more affordable than their forged counterparts and stronger than cast wheels.

STEP #1

STEP #2

STEP #3